durometer hardness testing standards|durometer shore a hardness tester : agencies Testing. Evaluating how your products and services meet and exceed quality, safety, sustainability and performance standards. Inspection. Validating the specifications, value and safety of your raw materials, products and assets. . Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. .

webBruno e Marrone. Então tá combinado assim. Eu vou cuidar de mim. E você vai cuidar da sua vida. Tá resolvido então. De acordo e comunhão. Melhor a despedida. Já é fato .

{plog:ftitle_list}

webWatch BTV, the official channel of Benfica, on your PC and enjoy live matches, exclusive interviews, and behind-the-scenes footage. BTV is the best way to follow your favorite .

what is a durometer material

The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, cellular .1. Scope. 1.1 This test method covers twelve types of rubber hardness measurement devices known as durometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R.1. Scope. ometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, .ISO 7619-1:2010 specifies a method for determining the indentation hardness (Shore hardness) of vulcanized or thermoplastic rubber by means of durometers using the A scale for rubbers in .

Standard Test Method for Rubber Property - Durometer Hardness. 1.1 This test method covers twelve types of rubber hardness measurement devices known as durometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. The .Testing. Evaluating how your products and services meet and exceed quality, safety, sustainability and performance standards. Inspection. Validating the specifications, value and safety of your raw materials, products and assets. . Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. .

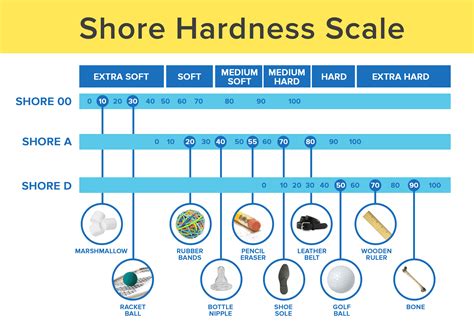

Loop Tack Tester sourcing

Standard Test Method for Rubber Property-Durometer Hardness: D2583: Standard Test Method for Indentation Hardness of Rigid Plastic by Means of a Barcol Impressor: E10: Standard Test Method for Brinell Hardness of Metallic Materials: E18: Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials: E92Thicker coatings are typically measured using an indentor-type tester such as a Durometer (ASTM D2240, Standard Test Method for Rubber Property – Durometer Hardness), which measures the resistance to indentation under a .Welcome to our ASTM D2240 testing services page for evaluating “Shore hardness” as part of our analysis of plastics and polymers.This standard, ASTM D2240, also known as “Rubber Property—Durometer Hardness,” allows for the measurement of a material’s hardness by indenting the material with a standardized tip under a defined force.The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless quantity. It goes between 0 and 100. The higher number of hardness represents the harder material.

Standard Test Method for Rubber Property Durometer Hardness 1 This standard is issued under the Þxed designation D2240; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.Measuring Durometer Hardness . Durometer hardness testing is performed according to the procedure described in ASTM D2240, . According to the ASTM standard, Durometer hardness values less than 20 and greater than 90 are not considered reliable and it suggests not recording readings below 20 and above 90 for either the Shore A or Shore D .

This test method covers twelve types of rubber hardness measurement devices known as durometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R.astmd2240152021-Standard Test Method for Rubber Property - Durometer Hardness- 1.1This test method covers twelve types of rubber hardness measurement devices kn D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries F1957 Test Method for Composite Foam Hardness-Durometer Hardness 2.2 ISO Standard: 3 ISO/IEC 17025: 1999 General Requirements for the Com-petence of Testing and Calibration Laboratories 3. Summary of Test MethodStandard Test Method for Rubber Property—Durometer Hardness1 This standard is issued under the fixed designation D2240; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

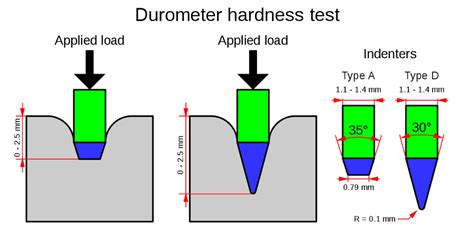

A spring-loaded indenter (called a durometer) is pressed into the material sample, and the depth of penetration is converted to a hardness value. Rockwell hardness test, a type of hardness test . ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: .

The hardness of plastics is most commonly measured by the Shore® (Durometer) test or Rockwell hardness test. Both methods measure the resistance of plastics toward indentation and provide an empirical hardness value that doesn't necessarily correlate well to other properties or fundamental characteristics.

ASTM D2240 durometers allow for a measurement of the initial hardness, or the indentation hardness after a given period of time. The basic test requires applying the force in a consistent manner, without shock, and measuring the hardness (depth of the indentation). If a timed hardness is desired, force is applied for the required time and then .This test method is not used to evaluate the hardness of coated materials. Utilizing this standard, hardness can be evaluated using the following types of durometers: Types A, D, and M. This method should not be compared to .Durometer Operating Stands; Durometer Test Block Kits; Multi-Scale Durometers; O-Ring Hardness Kits; Slim Probe Durometers; Reconditioned Durometers; Data Output Cable . Rex Gauge has been a leader in the .

shore a vs d durometer

In general terms, it outlines the preparation and configuration of the test specimen as well as the details of performing the durometer hardness test. Note: ASTM D2240 may be found in Volume 09.01 of the American Society for .The Durometer is the international standard for the hardness measurement of rubber, plastic and other non-metallic materials. Durometers are described in the American Society for Testing and Material specification ASTM D2240, which is the recognized specification for the instrument and test procedures. Rex Gauge Durometers Rex Durometers are known World-Wide for .

Standard Test Method for Rubber Property—Durometer Hardness1 . F1957 Test Method for Composite Foam Hardness-Durometer Hardness 2.2 ISO Standard:3 ISO/IEC 17025: 1999 General Requirements for the Com-petence of Testing and Calibration Laboratories 3. .The Shore (Durometer) test is the preferred hardness testing method for elastomers and is also commonly used for compliant plastics such as polyolefins, fluoropolymers, and vinyl polymers. Shore hardness testing is typically performed following ASTM [19] standards. The two most common test procedures are the Shore A and the Shore D scales. 1.1 This test method describes a type of composite foam hardness measurement device known as durometer: Type CF. The procedure for determining indentation hardness of substances comprised of two or more elastomeric materials, .The standard test specimen for most durometer types has a minimum thickness requirement of 6 mm. The specimen should also have flat, parallel surfaces that are at least 24 mm in diameter. Specimens for types M, OOO, and OOO-S can be as thin as 1.25 mm with a .

ASTM International - ASTM D2240-15(2021) Standard Test Method for Rubber Property-Durometer Hardness The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . This is done with the pointed tip of a durometer, which presses into the surface of your material and is controlled by a spring with a force that you or the operator will set. The depth of the indent that the pointed steel rod .

Standard Test Method for Rubber Property--Durometer Hardness. Our policy towards the use of cookies Accuris uses cookies to improve your online experience. . Standard Test Method for Rubber Property--Durometer Hardness. standard by ASTM International , 06/15/2021. View all product details Most .

To test for durometer hardness, an engineer places the needle against the elastomer or plastic and applies pressure. Once the needle has penetrated the material as much as it can, the measurement needle indicates the corresponding durometer hardness on the appropriate scale. . For example, a material with a durometer hardness of around 80 on . Standard Test Method for Rubber Property—Durometer Hardness D2240-03 ASTM|D2240-03|en-US Standard Test Method for Rubber Property—Durometer Hardness Standard D2240 Standard Test Method for Rubber Property—Durometer Hardness> new BOS Vol. 09.01 Committee D11 $ 91.00 In stock

shore a hardness chart

how to measure shore hardness

webVídeos Mais Recentes Marcados Com Bruna Vieira. Mostrar 1-3 de 3. 33:32. Latinas Fumantes Gostosas 6 - Cena 3. Combat Zone XXX. 4.8K Visualiz. 83%. 5:00. Bruna Vieira - Heavily Tattooed Latina Slut Anus Plugged.

durometer hardness testing standards|durometer shore a hardness tester